Sensor Traffic Piezoelectric don AVC (Rarraba Mota ta atomatik)

Takaitaccen Bayani:

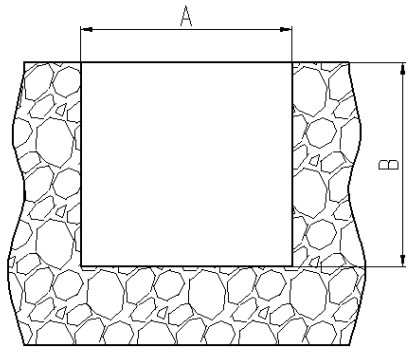

CET8311 na'urar firikwensin zirga-zirgar hankali an tsara shi don dindindin ko na wucin gadi akan hanya ko ƙarƙashin hanya don tattara bayanan zirga-zirga. Tsarin na musamman na firikwensin yana ba da damar sanya shi kai tsaye a ƙarƙashin hanya a cikin nau'i mai sassauƙa kuma don haka ya dace da madaidaicin hanya. Tsarin firikwensin firikwensin yana da juriya ga hayaniyar hanya ta hanyar lankwasa saman titin, hanyoyin da ke kusa, da lankwasa taguwar ruwa suna gabatowa abin hawa. Ƙananan ƙwanƙwasa a kan shimfidar wuri yana rage lalacewar hanya, yana ƙara saurin shigarwa, kuma yana rage adadin grout da ake buƙata don shigarwa.

Cikakken Bayani

Gabatarwa

CET8311 na'urar firikwensin zirga-zirgar hankali an tsara shi don dindindin ko na wucin gadi akan hanya ko ƙarƙashin hanya don tattara bayanan zirga-zirga. Tsarin na musamman na firikwensin yana ba da damar sanya shi kai tsaye a ƙarƙashin hanya a cikin nau'i mai sassauƙa kuma don haka ya dace da madaidaicin hanya. Tsarin firikwensin firikwensin yana da juriya ga hayaniyar hanya ta hanyar lankwasa saman titin, hanyoyin da ke kusa, da lankwasa taguwar ruwa suna gabatowa abin hawa. Ƙananan ƙwanƙwasa a kan shimfidar wuri yana rage lalacewar hanya, yana ƙara saurin shigarwa, kuma yana rage adadin grout da ake buƙata don shigarwa.

Fa'idar CET8311 firikwensin zirga-zirgar hankali shine cewa zai iya samun cikakkun bayanai na musamman, kamar ingantacciyar siginar sauri, siginar faɗakarwa da bayanin rarrabuwa. Yana iya mayar da martani ga kididdigar bayanan zirga-zirga na dogon lokaci, tare da kyakkyawan aiki, babban aminci da sauƙin shigarwa. Babban aiki mai tsada, galibi ana amfani da shi wajen gano lambar axle, wheelbase, sa ido kan saurin abin hawa, rarrabuwar abin hawa, awo mai ƙarfi da sauran wuraren zirga-zirga.

Gabaɗaya girma

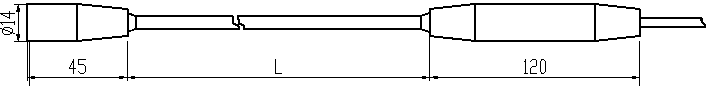

Misali: L=1.78m; Tsawon firikwensin shine mita 1.82; Tsawon duka shine mita 1.94

| Tsawon Sensor | Ganuwa Tsawon Brass | Tsawon Gabaɗaya (ciki har da ƙarewa) |

| 6'(1.82m) | 70'' (1.78m) | 76'' (1.93m) |

| 8'(2.42m) | 94'' (2.38m) | 100'' (2.54m) |

| 9'(2.73m) | 106'' (2.69m) | 112'' (2.85m) |

| 10'(3.03m) | 118''(3.00m) | 124'' (3.15m) |

| 11'(3.33m) | 130''(3.30m) | 136''(3.45m) |

Siffofin fasaha

| Model No. | QSY8311 |

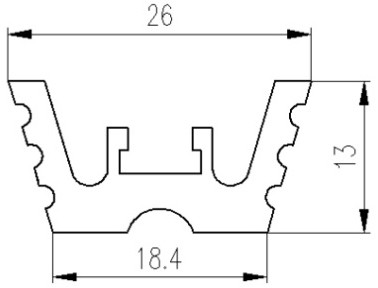

| Girman sashi | ~3 ×7mm2 |

| Tsawon | za a iya musamman |

| Piezoelectric coefficient | ≥20pC/N Ƙimar ƙima |

| Juriya na rufi | :500MΩ |

| Daidai da ƙarfin ƙarfin | ~6.5nf |

| Yanayin aiki | -25 ℃~60 ℃ |

| Interface | Q9 |

| madaurin hawa | Haɗa madaidaicin hawa tare da firikwensin (Ba a sake yin amfani da kayan nailan ba). 1 inji mai kwakwalwa kowane 15 cm |

Shirye-shiryen shigarwa

Zaɓin sashin hanya:

a) Bukatun akan kayan aikin aunawa: Dogon kwanciyar hankali da aminci

b) Bukatu akan gadon hanya: Rigid

Hanyar shigarwa

5.1 Yanke Ramin:

5.2 Tsaftace da bushe matakai

1, Domin tabbatar da cewa kayan aikin tukunyar za a iya haɗa su da kyau tare da hanyar hanya bayan cikawa, dole ne a wanke ramin shigarwa tare da mai tsabta mai mahimmanci, kuma a wanke saman tsagi tare da goga na karfe, kuma ana amfani da injin iska / bindigar iska mai ƙarfi ko busa bayan tsaftacewa don bushe ruwa.

2, Bayan an tsaftace tarkace, tokar da ke iyo a kan ginin ya kamata kuma a tsaftace. Idan akwai ruwa da aka tara ko kuma damshin da ake iya gani a fili, yi amfani da na'urar kwampreso ta iska (matsi mai ƙarfi) ko abin hurawa don bushewa.

3, Bayan an gama tsaftacewa, ana amfani da tef ɗin rufewa (nisa fiye da 50mm).

zuwa farfajiyar hanya a kusa da daraja don hana kamuwa da cuta ga grout.

5.3 Gwajin riga-kafi

1, Gwajin ƙarfin gwaji: Yi amfani da mitoci da yawa na dijital don auna jimlar ƙarfin firikwensin tare da kebul ɗin da aka haɗe. Ƙimar da aka auna ya kamata ta kasance cikin kewayon da aka ƙayyade ta daidai tsawon firikwensin da takardar bayanan kebul. Ana saita kewayon mai gwadawa yawanci zuwa 20nF. Jajayen binciken yana haɗa zuwa ainihin kebul ɗin, kuma binciken baƙar fata yana haɗa zuwa garkuwar waje. Lura cewa bai kamata ku riƙe ƙarshen haɗin biyu a lokaci guda ba.

2, Juriya na Gwaji: Auna juriya a duka ƙarshen firikwensin tare da multimita na dijital. Ya kamata a saita mita zuwa 20MΩ. A wannan lokacin, karatun akan agogo ya kamata ya wuce 20MΩ, yawanci ana nunawa ta “1”.

5.4 Gyara madaurin hawa

5.5 Mix grout

Lura: Da fatan za a karanta umarnin grout a hankali kafin haɗuwa.

1) Buɗe tukunyar tukunyar, gwargwadon saurin cikawa da adadin da ake buƙata, ana iya aiwatar da shi a cikin ƙananan adadi amma kaɗan kaɗan don guje wa sharar gida.

2) Shirya daidai adadin gwangwani na tukunya bisa ga ƙayyadaddun rabo, da kuma motsawa daidai da mai motsawar guduma na lantarki (kimanin minti 2).

3) Bayan shiri, da fatan za a yi amfani da sama a cikin mintuna 30 don guje wa ƙarfafawa a cikin guga.

5.6 Matakan ciko na farko

1) Zuba grout a ko'ina tare da tsawon tsagi.

2) Lokacin da ake cikawa, ana iya samar da tashar ruwan magudanar ruwa da hannu don sauƙaƙe sarrafa saurin gudu da alkibla yayin zubarwa. Don adana lokaci da ƙarfin jiki, ana iya zubar da shi tare da ƙananan kwantena masu iya aiki, wanda ya dace da mutane da yawa suyi aiki a lokaci guda.

3) Cikowar farko ya kamata ya kasance cike da ramummuka, kuma a sanya grout surface dan sama da shimfida.

4) Ajiye lokaci gwargwadon yiwuwa, in ba haka ba grout zai ƙarfafa (wannan samfurin yana da lokacin warkewa na yau da kullun na 1 zuwa 2 hours).

5.7 Matakan cika grout na biyu

Bayan grouting na farko ya warke sosai, lura da saman grout. Idan saman ya yi ƙasa da saman titin ko kuma saman ya yi haƙori, sake haɗa grout (duba mataki na 5.5) kuma yi cika na biyu.

Cika na biyu ya kamata ya tabbatar da cewa saman grout ya dan kadan sama da hanyar hanya.

5.8 Yin niƙa

Bayan an gama shigarwa mataki na 5.7 na rabin sa'a, kuma grout ya fara ƙarfafawa, ya yage kaset a gefen ramummuka.

Bayan shigarwa mataki 5.7 aka kammala na 1 hour, da grout solidified gaba daya, niƙa da

grout tare da kusurwar niƙa don sa shi ja da saman hanya.

5.9Tsaftar kan-site da gwaji bayan shigarwa

1) Tsaftace tarkace da sauran tarkace.

2) Gwaji bayan shigarwa:

(1) Gwajin iya aiki: yi amfani da mitoci da yawa na dijital don auna jimlar ƙarfin firikwensin tare da kebul ɗin da aka haɗe. Ƙimar da aka auna ya kamata ta kasance cikin kewayon da aka ƙayyade ta daidai tsawon firikwensin da takardar bayanan kebul. Ana saita kewayon mai gwadawa yawanci zuwa 20nF. Jajayen binciken yana haɗa zuwa ainihin kebul ɗin, kuma binciken baƙar fata yana haɗa zuwa garkuwar waje. Yi hankali kada ku riƙe haɗin haɗin biyu yana ƙare lokaci guda.

(2) Gwajin juriya: yi amfani da mitoci masu yawa na dijital don auna juriyar firikwensin. Ya kamata a saita mita zuwa 20MΩ. A wannan lokacin, karatun akan agogo ya kamata ya wuce 20MΩ, yawanci ana nunawa ta “1”.

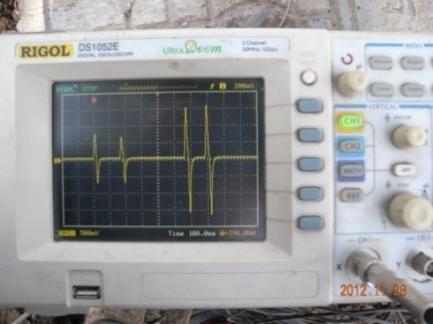

(3) Gwajin pre-load: bayan an tsabtace saman shigarwa, haɗa firikwensin firikwensin zuwa oscilloscope. Yanayin yanayin oscilloscope shine: Voltage 200mV/div, Time 50ms/div. Domin tabbataccen sigina, an saita wutar lantarki mai faɗakarwa zuwa kusan 50mV. Ana tattara nau'in nau'in nau'in igiyar mota da mota a matsayin nau'in gwaji na pre-load, sannan a adana na'urar gwajin a kwafi don bugawa, kuma a adana ta dindindin. Fitowar firikwensin ya dogara ne akan hanyar hawa, tsawon firikwensin, tsawon kebul da kayan tukunyar da aka yi amfani da su. Idan gwajin farko na al'ada ne, an gama shigarwa.

3) Sakin zirga-zirga: jawabai: Ana iya sakin zirga-zirgar ababen hawa ne kawai lokacin da kayan tukunyar suka warke sosai (kimanin sa'o'i 2-3 bayan cikawar ƙarshe). Idan an saki zirga-zirgar lokacin da kayan tukunyar ba su cika warkewa ba, zai lalata shigarwar kuma ya sa firikwensin ya gaza da wuri.

Preload gwajin kalaman kalaman

2 Gatari

3 Gatari

4 Gatari

6 Gatari

Enviko ya ƙware a Tsarin Ma'aunin-in-Motion sama da shekaru 10. An san firikwensin mu na WIM da sauran samfuran a cikin masana'antar ITS.