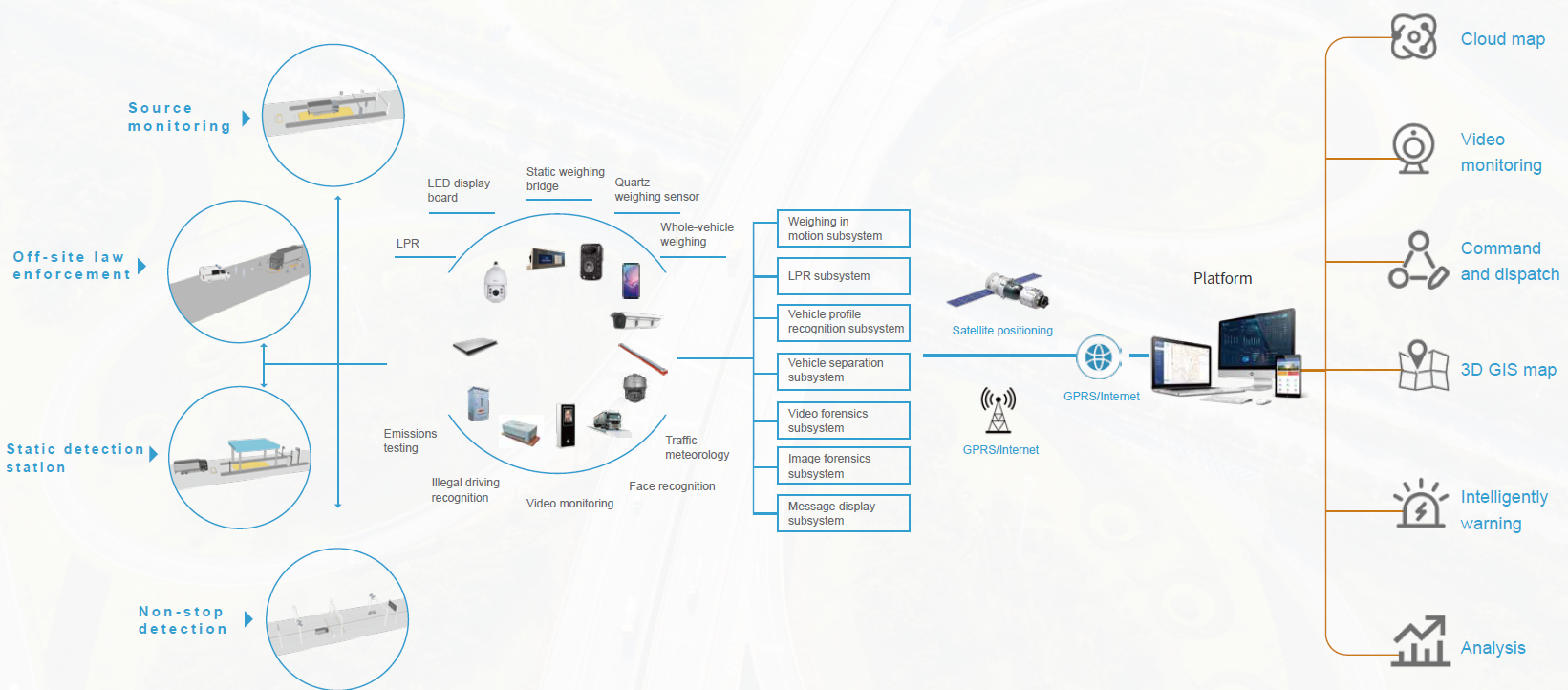

Tsarin ma'aunin ma'auni mai ƙarfi na Enviko (Tsarin Enviko WIM) babban madaidaicin tsarin awo ne wanda ya danganci na'urori masu auna firikwensin quartz, ana amfani da su sosai a fannin sufuri. Wannan tsarin yana amfani da na'urori masu auna firikwensin ma'adini na Enviko don auna ƙarfin ƙarfin abin hawa a cikin ainihin lokaci, ta yadda za a sami ingantaccen sa ido kan lodin abin hawa. Tsarin yana da inganci sosai, amintacce, da dorewa, yana taimakawa yadda yakamata wajen sarrafa sufurin hanya da kiyaye ababen more rayuwa na hanya.

Amfani

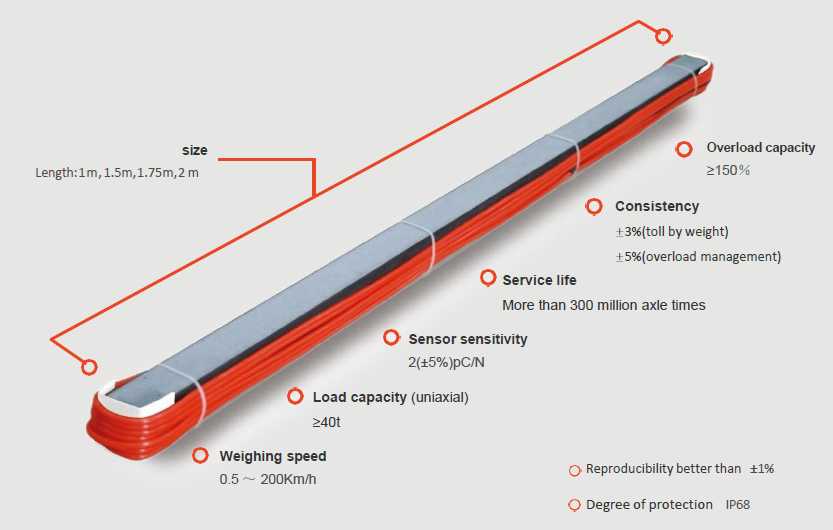

1.Babban Madaidaici: The Enviko Quartz Dynamic Weighing System yana amfani da na'urori masu auna firikwensin Enviko ma'adini, waɗanda ke da matuƙar hankali da daidaito, suna ba da damar ma'aunin nauyin abin hawa da kuma watsa bayanai na ainihin lokaci.

2.Dorewa: Enviko quartz na'urori masu auna firikwensin an yi su ne daga kayan inganci masu inganci tare da juriya mai kyau da juriya mai ƙarfi, yana tabbatar da kwanciyar hankali na dogon lokaci a cikin mahallin hanyoyi.

3.Sauƙin Shigarwa: Tsarin shigarwa na Enviko Quartz Dynamic Weighing System yana da sauƙi. Ta bin ƙayyadaddun matakan shigarwa, za a iya ƙaddamar da tsarin kuma za'a iya gyara shi da kyau.

4.Kulawa na Gaskiya: Tsarin zai iya kula da bayanan nauyin abin hawa a cikin ainihin lokaci kuma ya watsa bayanan zuwa tsarin kulawa ta tsakiya ta hanyar fasahar watsawa mara waya, sauƙaƙe nazarin bayanai da yanke shawara ta hanyar ma'aikatan gudanarwa.

5.Multi-Ayyukan: Baya ga aunawa, Enviko Quartz Dynamic Weighing System kuma yana nuna alamar abin hawa, ƙararrawa mai yawa, da ƙari, yana ba da cikakkiyar mafita don sarrafa zirga-zirga.

Matakan Shigarwa da Hanyoyi

Bukatun Fasaha na Binciken Yanar Gizo

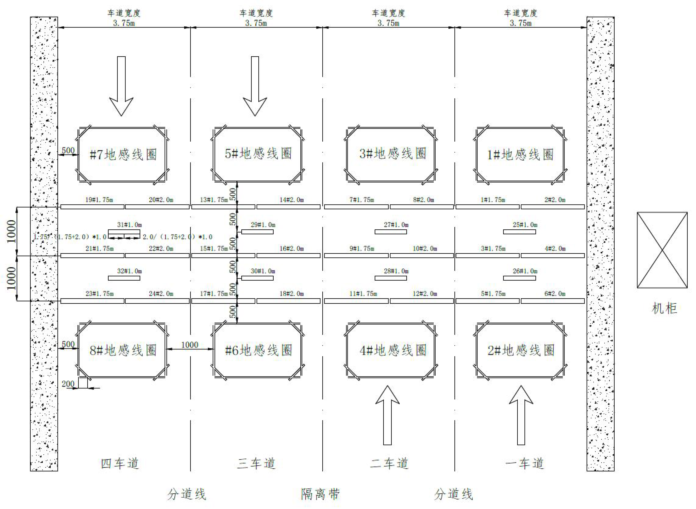

1.Zaɓin Yankin Auna: Tabbatar cewa wurin auna shine madaidaiciyar hanya ta mita 200-400 kafin da kuma bayan tashar auna, ba tare da tsaka-tsaki ba, don tabbatar da bin abin hawa a cikin wurin aunawa da inganta daidaiton auna.

2.LED Nuni Shigarwa: Ana ba da shawarar shigar da nunin LED mai nisan mita 250-500 a bayan wurin auna don sauƙaƙe direbobi a kallon bayanan nauyi.

3.Kauce wa Lanƙwasa da gangara: Zaɓi sassan hanya madaidaiciya don yin gini kuma ku guji shigar da tsarin auna akan lanƙwasa da gangara.

Abubuwan Bukatun Fasaha na Layout Sensor

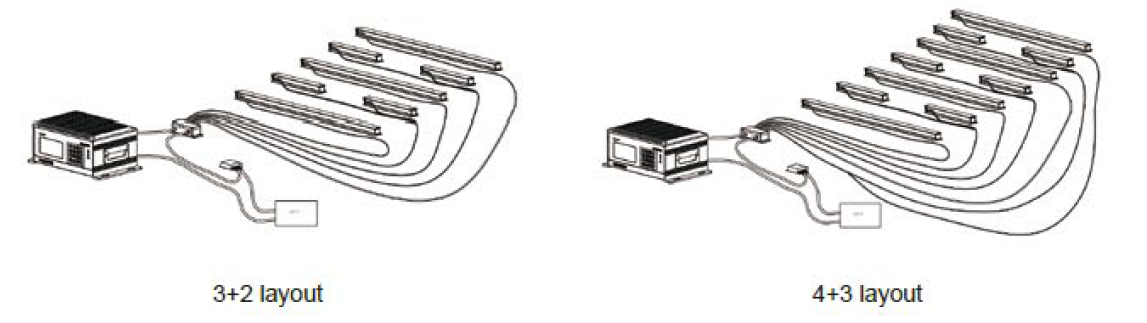

Na'urori masu auna sigina na Enviko Quartz Dynamic Weighing System sun ɗauki tsarin "3+2", tare da layuka uku cikakke, da tazarar mita 1 tsakanin kowane jere na firikwensin. A tsakiyar layuka uku, an shimfida na'urar firikwensin da tsayin mita 1 (don fadin layi daya kasa da mita 4.25) ko kuma mita 1.5 (don fadin layi daya sama da mita 4.25). Tsawon na'urori masu auna firikwensin yana rarraba daidai gwargwado kuma an daidaita shi tare da ƙarshen na'urori masu auna juzu'i, tare da tazarar mita 0.5.

Gyaran Hanyar Hanya

1.Yanayin Gina: Kammala aikin rufe hanya da karkatar da ababen hawa don tabbatar da shirye-shiryen kayan aikin gini da kayan aiki.

2.Tsarin Gina:

·Aunawa da Alama: Auna da alama bisa ga zane-zanen zane don tabbatar da daidaiton wurin ginin.

·Yanke Hanya da Karyewa: Yi amfani da injin yankan hanya don yanke a kusa da yankin, tare da zurfin yanke fiye da 10 cm, sa'an nan kuma karya hanyar hanya.

·Tushen Tsaftacewa da Matsayi: Tsaftace ramin tushe kuma daidaita shi ta amfani da matakin da theodolite don tabbatar da kwanciyar hankali.

·Kankare Zuba: Zuba simintin bisa ga buƙatun ƙira, tabbatar da cewa an zubar da simintin tushe a cikin tafi ɗaya, da yin rawar jiki da jiyya.

·Rebar Processing: Kwanta da ƙulla rebar bisa ga zane-zanen zane, tabbatar da daidaito da kwanciyar hankali na rebar raga.

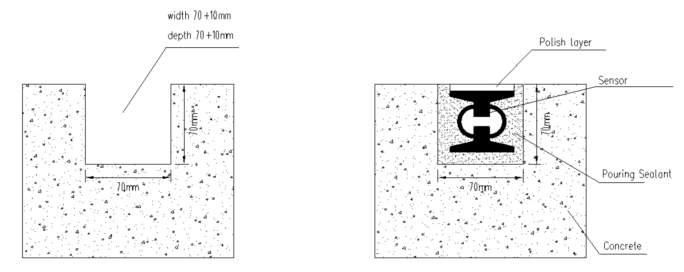

Tsarin Shigar Sensor da Buƙatun Fasaha

1.Tabbatar da Matsayin Sensor: Tabbatar da matsayi na shigarwa na na'urori masu auna firikwensin Enviko quartz bisa ga zane-zanen zane kuma yi musu alama.

2.Shigar da Sensor:

·Tushen Shigarwa: Shigar da tushe na firikwensin a kan tushe na kankare da aka zuba, tabbatar da tushe yana da matsayi da tsaro.

·Gyaran Sensor: Gyara na'urori masu auna firikwensin Enviko ma'adini a kan tushe kuma yi gyara na farko don tabbatar da na'urori masu auna firikwensin suna aiki daidai.

3.Haɗin Cable Data: Haɗa igiyoyin bayanan firikwensin kuma sanya igiyoyin zuwa tsarin kulawa na tsakiya, tabbatar da ingantaccen watsa bayanai.

4.Gyaran tsarin: Yi cikakken ɓarna na tsarin gaba ɗaya don tabbatar da aiki na yau da kullun na Enviko Quartz Dynamic Weighing System.

Kammalawa

Tsarin ma'auni mai ƙarfi na Enviko Quartz (Tsarin Enviko WIM), tare da babban madaidaicin sa, karko, da ayyuka da yawa, ya zama kayan aiki mai mahimmanci don sarrafa sufurin hanya. Ta hanyar bin matakai da hanyoyin da aka zayyana a cikin littafin shigarwa, ana iya tabbatar da tsayayyen aiki na tsarin da ingantacciyar ma'auni. Ayyukan na'urori masu auna firikwensin ma'adini na Enviko, a matsayin babban ɓangaren tsarin, yana tasiri kai tsaye da daidaito da amincin tsarin. Don haka, yayin shigarwa da amfani, yana da mahimmanci a yi aiki bisa ga buƙatun fasaha don cikakken amfani da fa'idodin Tsarin Ma'auni mai ƙarfi na Enviko Quartz (tsarin Enviko WIM).

Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Ofishin Chengdu: No. 2004, Raka'a 1, Ginin 2, Lamba 158, Tianfu 4th Street, Yankin Hi-tech, Chengdu

Ofishin Hong Kong: 8F, Ginin Cheung Wang, 251 San Wui Street, Hong Kong

Lokacin aikawa: Agusta-07-2024