1. Fasahar Baya

A halin yanzu, tsarin WIM da ya dogara da na'urori masu auna ma'aunin piezoelectric ana amfani da su sosai a cikin ayyuka kamar sa ido kan manyan gadoji da tarkace, tilasta yin amfani da wuce gona da iri na manyan motocin dakon kaya, da sarrafa wuce gona da iri na fasaha. Koyaya, don tabbatar da daidaito da rayuwar sabis, irin waɗannan ayyukan suna buƙatar sake gina shingen siminti don ma'aunin ma'aunin piezoelectric ma'aunin firikwensin shigarwa tare da matakin fasaha na yanzu. Amma a wasu wurare na aikace-aikacen, irin su gada ko hanyoyin mota na birni tare da matsananciyar cunkoson ababen hawa (inda lokacin aikin siminti ya yi tsayi da yawa, yana sa rufe hanyoyin na dogon lokaci da wahala), irin waɗannan ayyukan suna da wahalar aiwatarwa.

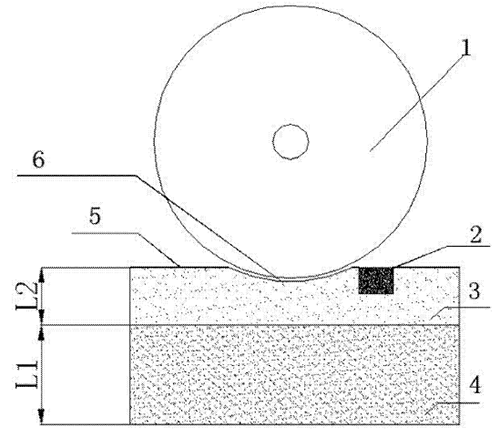

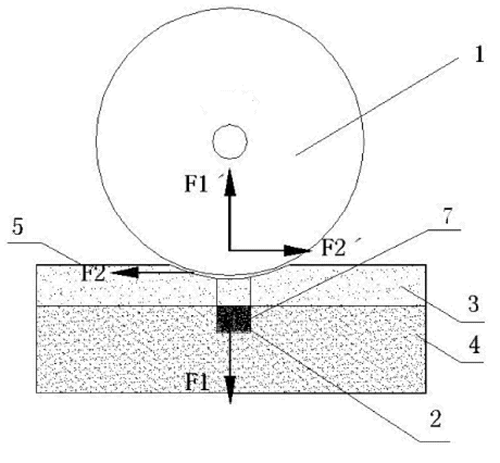

Dalilin da ya sa ba za a iya shigar da firikwensin ma'aunin ma'auni na piezoelectric kai tsaye akan shimfida mai sassauƙa ba shine: Kamar yadda aka nuna a hoto na 1, lokacin da dabaran (musamman a ƙarƙashin nauyi mai nauyi) ke tafiya a kan shimfidar sassauƙa, farfajiyar hanya za ta sami ɗan ƙarami babba. Koyaya, lokacin isa wurin ma'aunin firikwensin piezoelectric ma'auni, halayen subsidence na firikwensin da wurin mu'amalar matafiya sun bambanta. Bugu da ƙari, na'urar firikwensin ma'auni ba shi da mannewa a kwance, yana haifar da firikwensin auna ya karye da sauri ya rabu da pavement.

(1-wheel, firikwensin ma'auni 2, Layer tushe mai laushi 3, madaurin tushe mai ƙarfi 4, shimfida mai sassauƙa 5, yanki mai abinci 6, kushin kumfa 7)

Saboda halaye daban-daban na subsidence da maɓalli daban-daban na juzu'i, motocin da ke wucewa ta ma'aunin ma'aunin firikwensin piezoelectric suna fuskantar firgita mai tsanani, suna tasiri ga daidaiton auna gaba ɗaya. Bayan daɗaɗɗen abin hawa na dogon lokaci, wurin yana iya lalacewa da fashewa, yana haifar da lalacewar firikwensin.

2. Magani na Yanzu a Wannan Filin: Sake Gina Pavement Siminti

Saboda matsalar piezoelectric quartz auna na'urori masu auna firikwensin rashin iya shigar kai tsaye a kan titin kwalta, babban ma'aunin da aka ɗauka a cikin masana'antar shine sake gina layin siminti don ma'aunin ma'aunin firikwensin piezoelectric. Tsawon sake ginawa gabaɗaya shine mita 6-24, tare da faɗi daidai da faɗin hanya.

Ko da yake ciminment ɗin da aka sake ginawa ya cika buƙatun ƙarfi don shigar da ma'aunin ma'aunin piezoelectric ma'auni kuma yana tabbatar da rayuwar sabis, batutuwa da yawa suna dagula haɓakar haɓakarsa, musamman:

1) Faɗakarwar gyare-gyaren tauraruwar siminti na asali na pavement yana buƙatar adadi mai yawa na farashin gini.

2) Sake gina siminti na buƙatar lokaci mai tsawo sosai. Lokacin warkewa don shimfidar siminti kawai yana buƙatar kwanaki 28 (misali buƙatun), babu shakka yana haifar da tasiri mai mahimmanci akan ƙungiyar zirga-zirga. Musamman a wasu lokuta inda tsarin WIM ya zama dole amma zirga-zirgar zirga-zirgar kan yanar gizo yana da girma sosai, ginin aikin yana da wahala.

3) Rushewar tsarin hanya na asali, yana shafar bayyanar.

4) Canje-canje kwatsam a cikin ma'auni na juzu'i na iya haifar da abubuwan ban mamaki, musamman a yanayin damina, wanda ke haifar da haɗari cikin sauƙi.

5) Canje-canje a tsarin hanya yana haifar da girgizar abin hawa, wanda ke shafar daidaiton aunawa zuwa wani matsayi.

6) Ba za a iya aiwatar da aikin sake gina siminti a wasu takamaiman hanyoyi ba, kamar gadoji masu tsayi.

7) A halin yanzu, a fagen zirga-zirgar ababen hawa, abin ya kasance daga fari zuwa baƙar fata (canza titin siminti zuwa titin kwalta). Maganin yanzu shine daga baki zuwa fari, wanda bai dace da bukatun da suka dace ba, kuma sassan gine-gine suna da tsayayya.

3. Ingantattun Abubuwan Tsarin Shigarwa

Manufar wannan makirci shine don magance rashi na piezoelectric quartz auna na'urori masu auna firikwensin da ba za a iya sanya su kai tsaye a kan shingen kwalta ba.

Wannan makirci yana sanya firikwensin ma'aunin ma'aunin piezoelectric kai tsaye a kan madaidaicin tushe mai tushe, yana guje wa batun rashin jituwa na dogon lokaci wanda ya haifar da shigar da tsayayyen tsarin firikwensin kai tsaye a cikin shimfidar shimfidar wuri. Wannan yana faɗaɗa rayuwar sabis sosai kuma yana tabbatar da cewa ba a shafar daidaiton aunawa.

Bugu da ƙari, babu buƙatar yin aikin sake gina kwalta na siminti a kan titin kwalta na asali, da adana adadi mai yawa na farashin gine-gine da kuma rage yawan lokacin gine-gine, yana ba da dama ga babban matsayi.

Hoto 2 zane ne na tsari tare da firikwensin ma'auni na piezoelectric wanda aka sanya akan madaidaicin tushe mai laushi.

(1-wheel, firikwensin ma'auni 2, Layer tushe mai laushi 3, madaurin tushe mai ƙarfi 4, shimfida mai sassauƙa 5, yanki mai abinci 6, kushin kumfa 7)

4. Mabuɗin Fasaha:

1) Ƙaddamar da ƙaddamarwa na tsarin tushe don ƙirƙirar ramin sake ginawa, tare da zurfin rami na 24-58 cm.

2) Daidaita kasan ramin da zub da kayan filler. Daidaitaccen rabo na yashi ma'adini + bakin karfe yashi resin epoxy ana zuba shi a cikin kasan ramin, cike da ko'ina, tare da zurfin filler na 2-6 cm kuma an daidaita shi.

3) Zuba madaidaicin tushe mai tushe da shigar da firikwensin awo. Zuba madaidaicin madaurin tushe kuma sanya firikwensin awo a ciki, ta amfani da kumfa kumfa (0.8-1.2 mm) don raba sassan firikwensin awo daga madaidaicin tushe. Bayan madaidaicin gindin Layer ɗin ya ƙarfafa, yi amfani da injin niƙa don niƙa firikwensin awo da madaidaicin tushe zuwa jirgin sama ɗaya. Ƙaƙƙarfan ƙaƙƙarfan Layer na iya zama maɗaukaki, tsaka-tsaki, ko haɗin tushe.

4) Simintin gyaran fuska. Yi amfani da kayan da ya yi daidai da madaurin tushe mai sassauƙa don zuba da cika ragowar tsayin ramin. A yayin aikin zubar da ruwa, yi amfani da ƙaramin na'ura don haɗawa a hankali, tabbatar da matakin gabaɗayan saman da aka sake ginawa tare da sauran filayen hanya. Matsakaicin tushe mai sassauƙa shine matsakaicin-lafiya ƙwalwar ƙwalwar ƙasa.

5) The kauri rabo daga m tushe Layer zuwa m tushe Layer ne 20-40: 4-18.

Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Ofishin Chengdu: No. 2004, Raka'a 1, Ginin 2, Lamba 158, Tianfu 4th Street, Yankin Hi-tech, Chengdu

Ofishin Hong Kong: 8F, Ginin Cheung Wang, 251 San Wui Street, Hong Kong

Ma'aikata: Gini 36, Jinjialin Industrial Zone, Mianyang City, lardin Sichuan

Lokacin aikawa: Afrilu-08-2024